Customisation and circularity as drivers for the future of plastics

PAG

The plastics industry is undergoing a fundamental transition. Standard solutions are increasingly failing to meet customer requirements, while sustainability, circularity and chain responsibility are becoming the norm. We see it as our task to provide direction in this changing market.

By combining specialist customisation with integrated circular solutions, we position ourselves as a future-oriented partner in the plastics chain.

Customisation as a distinguishing feature

We believe that the future of plastics lies in customer-specific solutions. Podt Alplain plays a key role in this by developing customisation without restrictions in terms of material choice, processing or application. This freedom makes it possible to realise solutions for existing applications as well as innovative or niche markets where standard products fall short. Customisation thus becomes a strategic starting point that sets us apart.

Collaboration as an accelerator of innovation

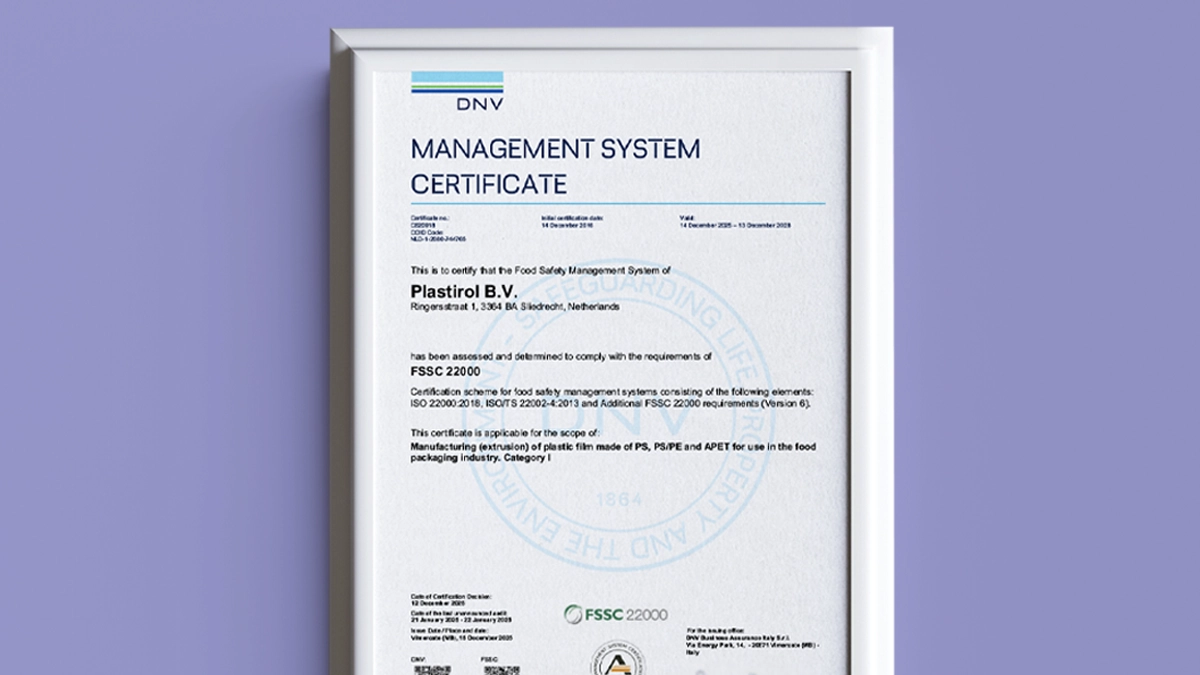

We consist of four independently operating brands, each with its own expertise in the plastics chain: Podt Alplain Kunststoffen, Plastirol Nederland/België, Hagedorn Plastirol and Redisol. By connecting these brands under one group structure, we create a powerful collaborative model in which knowledge, capacity and innovation reinforce each other.

Multiple links in the chain

This synergy enables end-to-end solutions: from reuse and material analysis to product development and extrusion. Customers benefit from a single partner that controls multiple links in the chain, while internal collaboration leads to faster innovation and better-tailored, future-proof products.

Circularity as an integral part

For us, sustainability is more than just an additional theme; it is an integral part of our business operations. Circularity is the common thread in our products and services. Redisol plays a central role by recycling and upcycling plastic residues into high-quality raw materials, while maintaining material quality.

Structural reuse of residual materials

In addition, Plastirol and Hagedorn Plastirol have processes in place to structurally reuse residual materials within their own production. By incorporating circularity as early as the design phase, we support our customers in achieving concrete, measurable sustainability goals: from raw material to semi-finished product and/or end product.

Responding to market developments and regulations

We actively anticipate important market trends that will be decisive in the coming years. European regulations are increasingly focused on reuse and circularity, while customers in sectors such as construction, automotive, engineering and packaging are increasingly demanding sustainable and recycled materials. At the same time, technological developments in extrusion, sorting and material analysis are making it possible to reuse more complex plastic streams in high-quality applications.

Link in the circular chain

We see our future as a connecting link in the circular plastics industry. By recycling materials, by thinking together with our customers about design and by considering material choice and product lifespan. By structurally combining expertise, collaboration and sustainability, we contribute to an industry in which quality, customisation and circularity go hand in hand.

In a market where many players opt for scale and standardisation, we consciously choose specialisation, customisation and integrated circular chains. This strengthens our competitive position and makes the PA Group relevant in the long term!

English

English Français

Français Deutsch

Deutsch Nederlands

Nederlands